BakerRisk Overview#

BakerRisk is a consulting company based in San Antonio that specializes in hazard and risk assessment, including equipment failure, toxic material spills, structural response, and explosion hazards. Clients across industries turn to BakerRisk for process safety advice and for studying how hazards affect their operations and products.

To support this work, BakerRisk operates two dedicated testing facilities where full-scale experiments are conducted each year. These tests generate data used both to develop safety procedures for hazardous materials and to evaluate how structures respond under extreme conditions. Testing is broadly divided into three groups: Process Safety, Structures, and Blast. Process Safety focuses on mitigation procedures, Structures investigates building response and design, and the Blast group studies explosion phenomena and is where I spent most of my time.

During my internship, I split time between two test sites:

- Wilfred E. Baker (WEB) site — east of San Antonio, home to the Shock Tube.

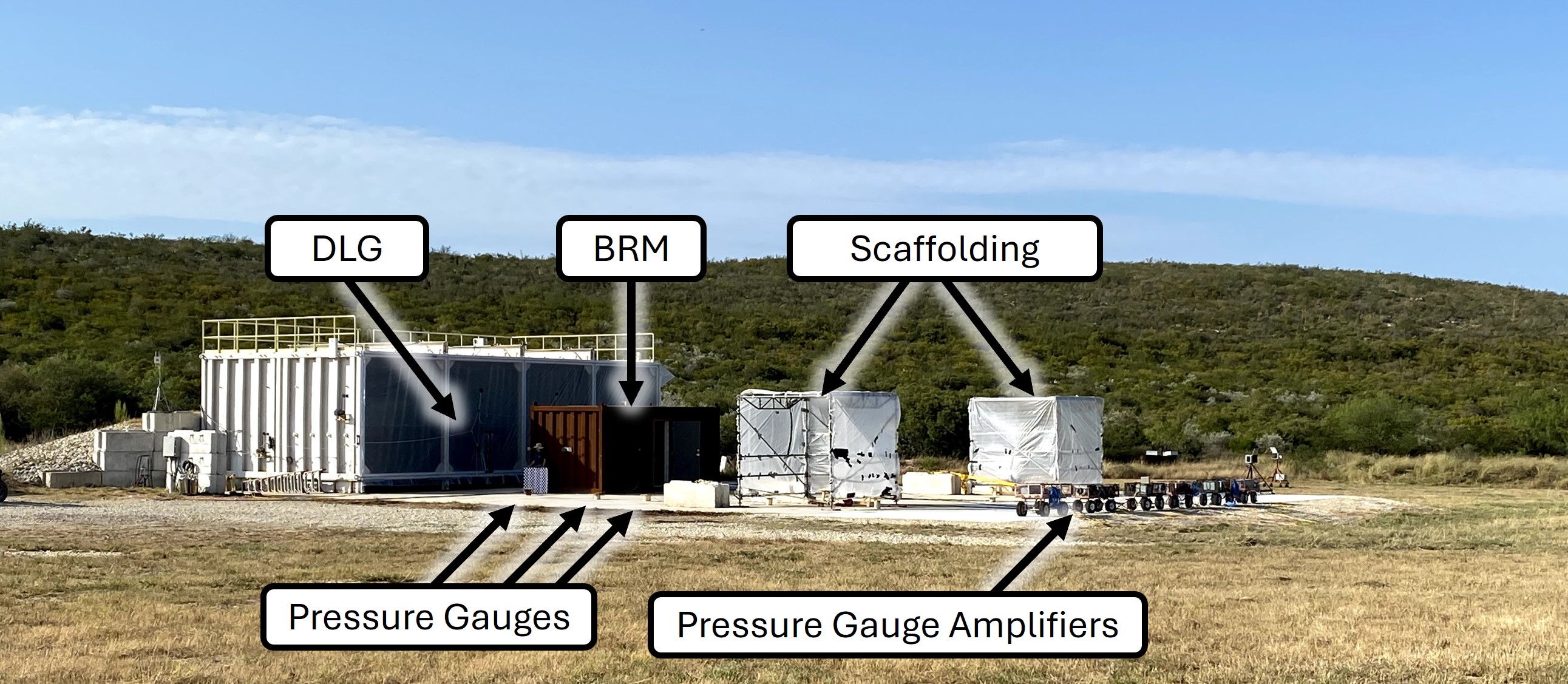

- Box Canyon Test Facility — west of Uvalde, home to the Deflagration Load Generator (DLG).

The DLG simulates pressure waves from vapor cloud deflagrations, while the Shock Tube produces controlled air-blast loads with a high-pressure driver. Both are used to push safety-critical structures and materials to their limits.

Box Canyon Projects#

The Deflagration Load Generator (DLG)#

The DLG is a combustion-driven pressure wave generator: an airtight steel chamber with one open end facing the test pad. By varying internal congestion (pipes or obstacles), flame speeds and blast loads can be controlled. Higher congestion produces faster flame fronts and stronger pressure waves.

Gas sampling ports within the DLG monitor the fuel–air mixture, while plastic sheeting seals the opening before ignition. Tests are triggered remotely, blasting whatever specimen is on the pad.

DLG Testing Group 1 — Blast Resistant Module & Scaffolding#

My first project was testing an anchored Blast Resistant Module (BRM). The goal was to characterize its response to explosions on a work site. Previous tests had used an unanchored BRM that slid across the pad; this time, the rectangular module was fixed to the ground with six 1-inch bolts. We recreated the same loads to compare anchored vs. unanchored responses.

Twelve pressure gauges were mounted on each non-loaded face with two inside and five on the loaded face.

To maximize efficiency, the BRM tests were combined with a separate study on standard scaffolding structures commonly used as temporary shelters. Both test setups shared the same DLG platform.

DLG Testing Group 2 — Baseline Tests#

Without internal congestion, the flame cannot accelerate into a detonation, and the DLG produces only a large fireball—seen in the stills below. This run is used by the test engineers to calibrate the response of the system without the congestion.

Most of my work with the DLG involved working independently in the field with one other intern, Tyler. We communicated with the full-time engineers over radio and were reponsible to the setup and calibration of the pressure guages mounted throughout the test pad, checking dessicant levels in the fuel delivery system, and maintenance of the test abort chord (a simple remote winch that would tear the plastic to vent any contained gas).

WEB Projects — The Shock Tube#

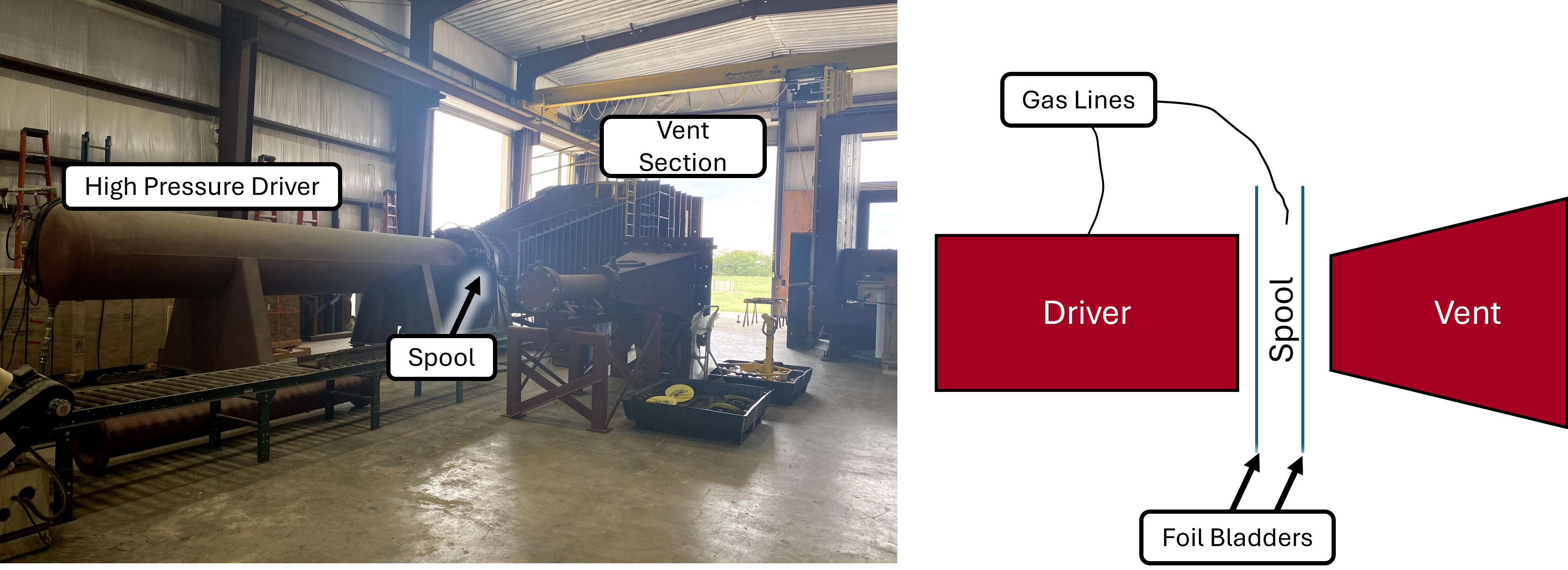

The Shock Tube subjects samples to precisely controlled blast pressures and impulses. Unlike the DLG, it uses compressed air rather than combustion.

It consists of three main sections:

- Driver — pressurized air chamber.

- Spool — buffer section.

- Vent — open-ended test section.

The sections are separated by thin aluminum foils that rupture at specific pressure differences (e.g., 0.018-in foil breaks at ~20 psi). By stacking foils and pre-pressurizing the spool, precise load conditions can be generated. Once the foils rupture, the load propagates into the vent and onto the specimen.

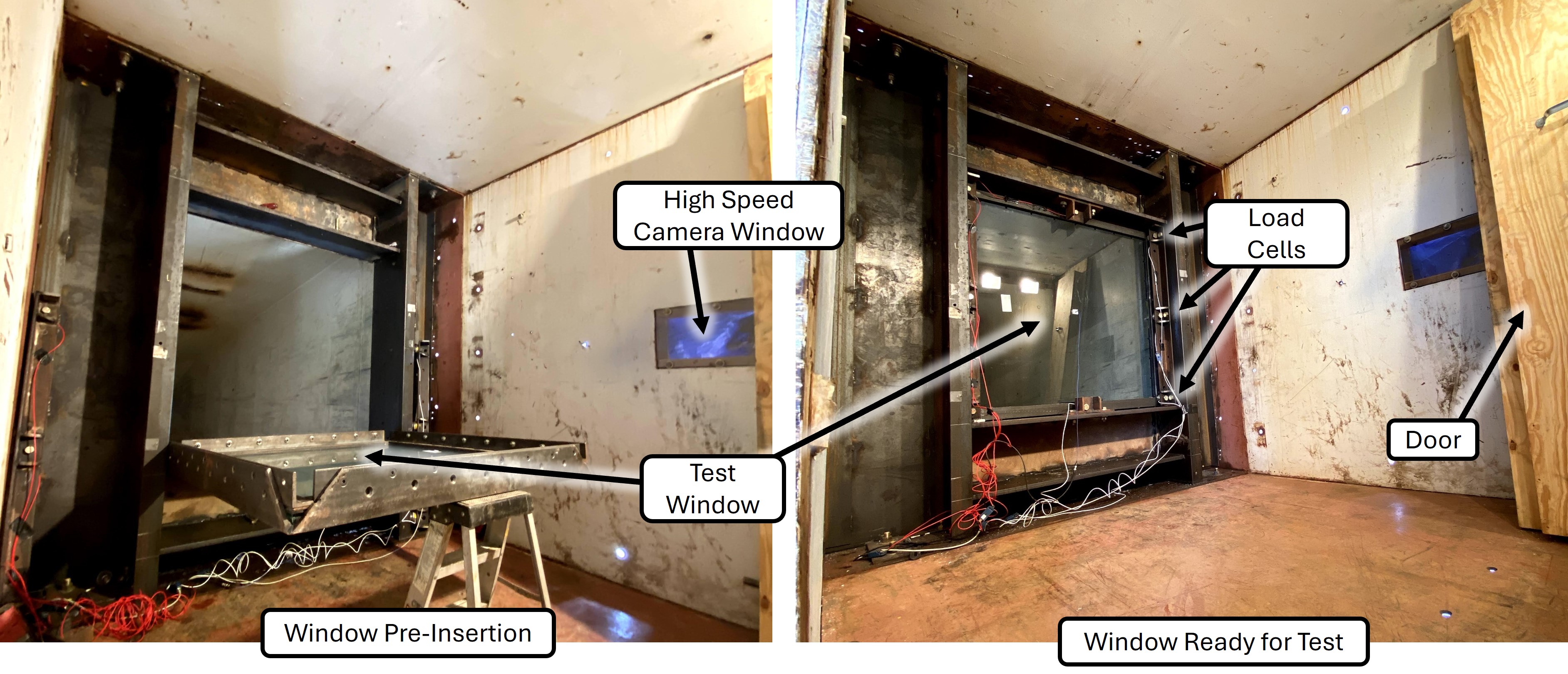

Ballistic Glass Testing#

One major program focused on the response of treated and laminated glass of varying thickness under different shock loads. Glass panes were mounted in a dual nested steel frame held against the shock tube. The frame was unbolted, allowing slight movement so that load cells could record edge forces on the glass.

My role in this project involved wiring the window frames with load cells and slow-motion video cameras. Even after flying glass would occasionally cut the wires. Additionally, Tyler and I assissted full time staff with the repeated trials of preparing and testing the windows.

Fortress Wall Pouring & Testing#

This program investigated reinforced wall sections designed for high-blast environments. Test panels were poured, cured, and subjected to shock loads at WEB to assess their resistance.

My role in this involved tying the internal rebar frame together and pouring the concrete required. I’m glad I’m not a civil engineer.